Redwire is accelerating humanity’s expansion into space by delivering reliable, economical and sustainable infrastructure for future generations.

WHAT WE DO

Integrated Mission Enabler

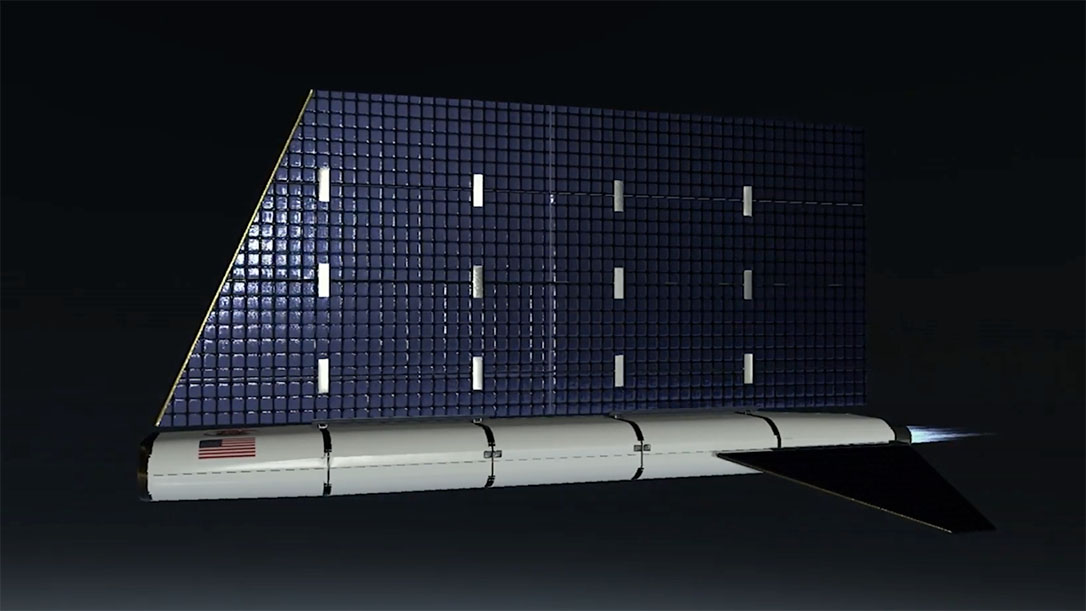

Redwire is a key mission enabler with products relevant to almost every space mission, including: power generation, antennas, deployable solutions, star trackers, and camera systems.

WHAT WE DO

Explore, Live, and Work in Space for the Benefit of Humanity

Redwire is developing capabilities that are critical for people to live and work in space which includes microgravity payloads, platforms, and in-space manufacturing and biotech facilities.

WHAT WE DO

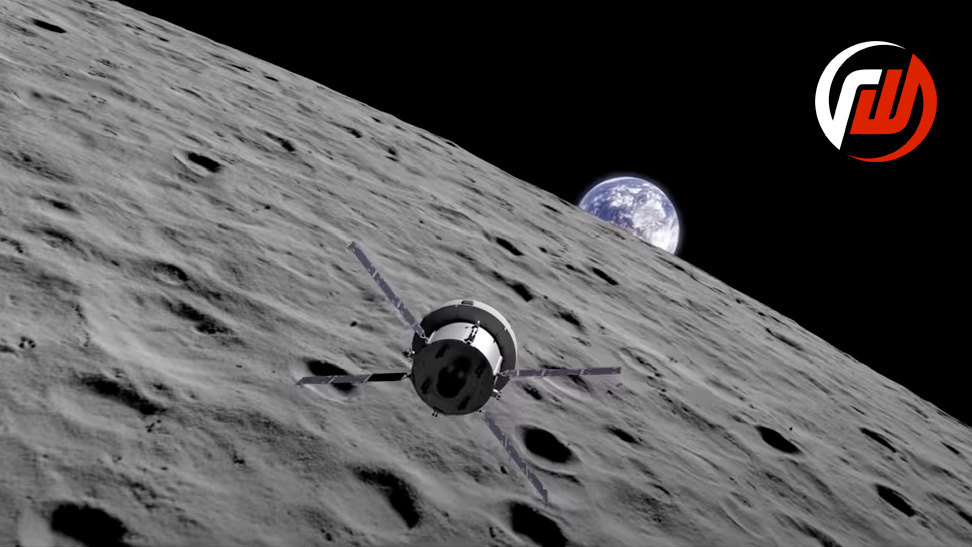

Multinational Mission Support

Redwire is supporting ambitious, multinational space exploration through products that are critical to international mission operations.

Headlines

Discover How Redwire Is Transforming the Future of Space Infrastructure.

Latest Investor News & Information

Heritage + Innovation

We Are the Mission Partner of Choice for Civil, Commercial, and National Security Space.

Play Video

What We Do

Redwire is the Mission Partner of Choice for Civil, Commercial, and National Security Space.

Redwire is a global, pure-play leader in space infrastructure – we provide the foundational solutions, systems, and payloads that enable the most complex space missions.

Redwire’s broad and diverse portfolio of innovative technologies is accelerating space development from Low Earth Orbit to the Moon, and beyond.

Countries will require an agile and innovative partner with decades of experience developing scientific and commercial payloads for the ISS and beyond – Redwire can be that partner.

Stay Informed.

Subscribe to our newsletter and keep pace with one of the most innovative and fastest growing space companies on and off Earth.